Search This Supplers Products:BMS Boardaluminium pcbflex PCB boardsmultilayer PCBPCB AssemblyPCB Reverse Engineering

Something about V-CUT

time2018/06/20

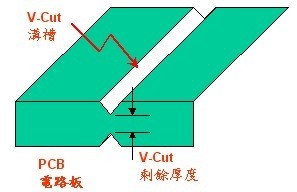

- Printed circuit board manufacturer according to customer's drawings requirements, advance in specific location with rotary cutting tool good PCB whole line, because of its appearance looks like after cutting a "V" word in English, hence the name

1. The purpose of designing v-cut and the operation of v-cut

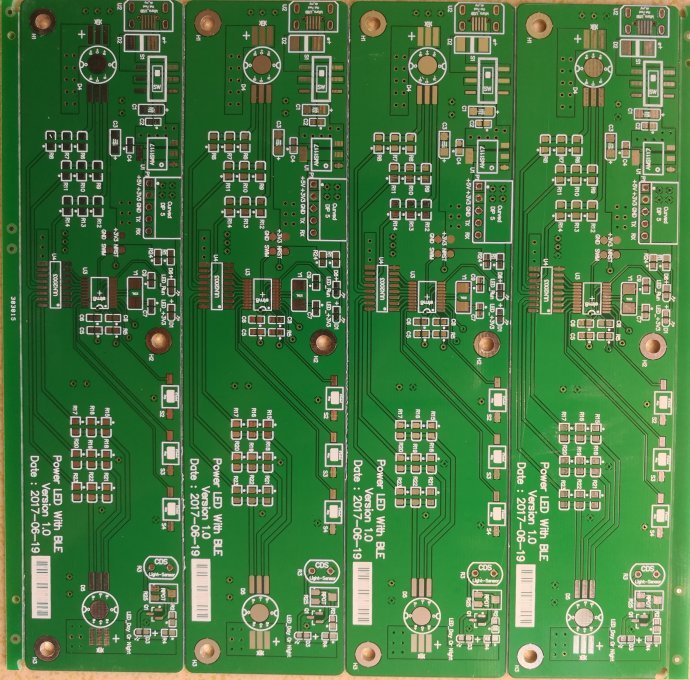

Design the main purpose of the V - cut in helping a convenient member points after PCB assembly board, board PCB points tend to use the Scoring machine, cut the PCB in advance good v-shaped grooves of Scoring circular blade, and then push hard in the past, some machines are automatically send board design, as long as a button, the blade will automatically move across the location of the circuit board V - cut cut the board, the height of the blade can be adjusted up and down in accordance with different V - the thickness of the cut.

Although PCB V - Cut above can also be used to manually, the fracture or break off, but it is strongly recommended that do not use, because it is because of the screws manually bent on PCB, it is very easy to cause PCB above electronic parts is broken, and especially capacitance parts, thus reduce the yield and reliability of the products, some problems and even to use after a period of time will gradually emerge.

2. Restrictions on v-cut design and use

Only cut a straight line and a knife to the end, that is to say, can only be cut into a straight line from head to tail, it cannot turn to change direction. Because of PCB cutting are very pure commonly so if it is more complex to cut off the path and will switch to Routing machine to plate.

The thickness is too thin and not suitable for V - Cut grooves, generally if the thickness of 1.0 mm below the board is not recommended to do, this is because the strength of grooves can destroy the structure of the original PCB, when design V - Cut boards placed above are heavy parts, because the relationship between gravity and makes it easy to plate bending, this very bad SMT welding operation, easy to cause an empty welding or short circuit).

In through the back to the high temperature of welding furnace. The PCB, the board itself will softening deformation because of the high temperature more than glass transition temperature, if V - Cut position and depth of the groove design well, will make the PCB deformation are more serious, adverse secondary to welding process.

3. Design and suggestion of residual thickness of v-cut

V Angle definition, in general there are 30 °, 45 °, 60 ° three Angle can be defined, the most commonly used for 45 °.

The larger the v-cut Angle is, the more boards are eaten at the edge of the board, and the lines on the relative PCB must be shrunk more inward to avoid damage when Cut or Cut.

Maybe it’s helpful to you:

Web link