Search This Supplers Products:BMS Boardaluminium pcbflex PCB boardsmultilayer PCBPCB AssemblyPCB Reverse Engineering

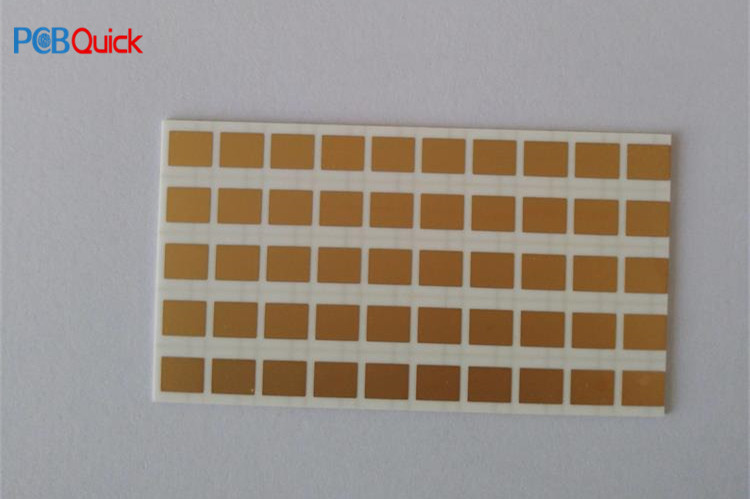

Thick Film Ceramic Material PCB

- group name

- Special PCB Manufacturing

- Min Order

- 1 piece

- brand name

- PCBQuick PCB Manufacturing and Assembly

- model

- KF-PCB

- Nearest port for product export

- SZ

- Delivery clauses under the trade mode

- FOB, EXW, DDU, Express Delivery

- Acceptable payment methods

- T/T, PayPal, Westem Union, Cash, Escrow

- Export mode

- Export through agents

- update time

- Fri, 30 Jul 2021 11:51:26 GMT

Paramtents

Material Aluminium oxide/Aluminium nitride

Ceramic Thickness 0.2mm/0.38mm/0.5mm/0.635mm/0.86mm/1.0mm

Copper Side single/double

Soldermask Color Non/White/Red/Green/Yellow/Black

Surface Technics ENIG/Plating Copper/Plating Gold/Plating Gold Tin

Min.Line Width .07mm

Packging & Delivery

-

Min Order1 piece

Briefing

electric power electronic control module;

high power LED;electric power transmitter modules;Solar-panel arrays

high power LED;electric power transmitter modules;Solar-panel arrays

Detailed

Ceramic Material PCB is a kind of composite substrate made by directly sintering copper foil to the surface of Aluminium oxide or Aluminium nitride at high temperature through hot melt adhesion.

1. Good mechanical strength

2. Good electrical insulation

3. Good thermal conductivity and thermal stability

4. Good resistance to erosion and abrasion

5. The coefficient of thermal expansion is close to silicon

6. Various patterns can be etched like glass fiber PCB

Application Of Ceramic Material PCB

1. High-power power semiconductor module; Semiconductor refrigerator, electronic heater; Power control circuit, power hybrid circuit.

2. Intelligent power components; High frequency switching power supply, solid relay

3. Automotive electronics, aerospace and military electronic components.

4. Solar panel components; Telecommunications PBX, receiving system; Laser and other industrial electronics

Ceramic Material PCB available, open cooling application the development of the industry, because of the ceramic substrate cooling characteristics, combined with ceramic substrates with high heat dissipation, low thermal resistance, long service life, the advantages of resistance to voltage, with the improved production technology, equipment, product prices accelerate rationalization, and enlarge the application field of LED industry, such as the indicator of electrical appliances product, car lights, street lamps and outdoor large billboards, etc. The success of the development of ceramic substrates will provide services for indoor lighting and outdoor lighting products, making the future market of LED industry broader.